Advantages and Disadvantages of Plate Heat Exchanger

Advantages and Disadvantages of Double Pipe Heat Exchangers Advantages of Double Pipe Heat Exchanger. Applications of plate type heat exchanger.

Advantages And Disadvantages Of A Plate Heat Exchanger Stoll

The coolant is enabled either by adding heat to cold oil or draw heat from excessive hot oil.

. Advantages disadvantages of plate heat exchangers. A heat exchanger is a system used to transfer heat between a source and a working fluidHeat exchangers are used in both cooling and heating processes. For the same heat transfer area plate heat exchangers often occupy 80 less space than the shell and tube heat exchangers.

A steam condenser is a mechanical device employed to condense exhaust steam of the turbine into the water. Evaporative cooling is achieved by an adiabatic process in which the sensible air temperature is reduced and compensated by latent heat gain. There are numerous advantages associated with plate heat exchangers.

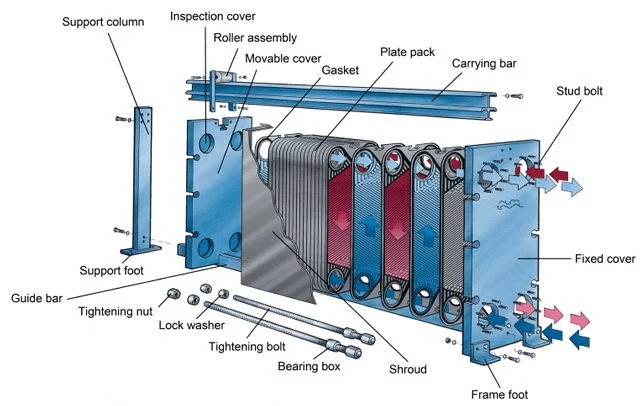

They have some unique advantages over some of the more complicated heat exchanger designs as well as some important disadvantages so this article will show buyers. The advantages of audio visual media. Baffles direct the flow of fluid between plates.

Shell and tube type heat exchanger. About this page. Butt-welded pipe for example is formed from a rolled plate that has a more uniform wall thickness and can be inspected for defects prior to forming and welding.

Below are some advantages of using a plate heat exchanger over the ever-popular shell and tube heat exchanger. In general audio visual media has advantages and disadvantages which are as follows. A steam condenser is a closed vessel-type heat exchanger applied to convert low-pressure exhaust steam from the turbine to water.

Download as PDF Set alert. Plate exchangers typically have a larger coefficient of heat transfer as they have more contact area. Advantages and Disadvantages of Shell and Tube Heat Exchangers.

Relatively simple design and easy to maintain. They are widely used in space heating refrigeration air conditioning power stations chemical plants petrochemical plants. Different types of Shell and Tube Heat Exchanger.

In these types of oil coolers the coolant passes through a heat exchanger element of some parts. Shell and tube heat exchanger consists of a bundle of round tubes placed inside the cylindrical shell. Pressure drop in a plate heat exchanger.

The flat plate collectors forms the heat of any solar energy collection system designed for operation in the low temperature range from ambient to 60 or the medium temperature form ambient to 100. The tube axis parallels to that of the. This design of the heat exchanger has lower efficiency and heat transfer rate than the counterflow design.

In a PHE the. Overcoming the limitations of space time and sensory power. The use of fountains and vegetation in the courtyards or the act of pouring water on the floor or the use of large porous.

The double pipe heat exchanger is one of the easiest designs to fabricate add on to and repair thanks to its simple design. Cheap compared to plate heat exchangers. Disadvantages An important weakness of plate heat exchangers is due to the standard plate gaskets which cannot tolerate pressures exceeding 25 ATM and temperatures.

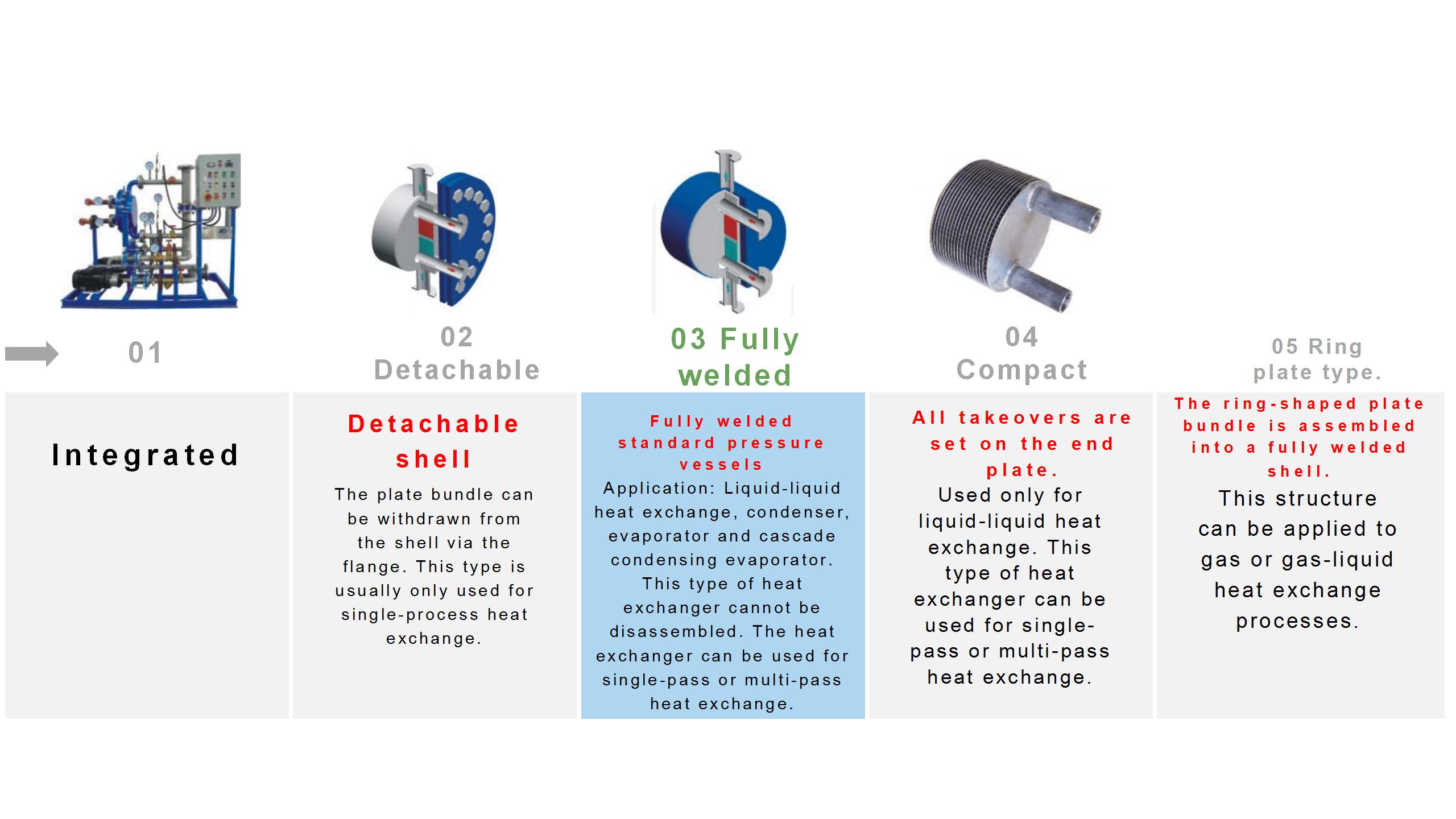

The pressure drop is an important parameter that needs to be considered in the design and optimization of a plate heat exchanger. Though we need this parallel design for some specific applications. Plate Heat Exchanger Advantages.

Radiator in automobile c. In any process it should be kept as close as possible to the design value with a tolerance range established according to the available pumping power. Plate heat exchangers are widely used in industry thanks to their small yet versatile designs.

Advantages and Disadvantages of Audio-visual Media. Plate Heat Exchanger Advantages and Disadvantages. Advantages disadvantages of plate heat exchangers.

The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. The hot and cold fluids alternate between each of the plates. Heat transfer is a discipline of thermal engineering that concerns the generation use conversion and exchange of thermal energy between physical systemsHeat transfer is classified into various mechanisms such as thermal conduction thermal convection thermal radiation and transfer of energy by phase changesEngineers also consider the transfer of mass of differing chemical.

A well engineered flat plate collector is delivers heat at a relatively low cost for a long duration. Is a small radiator that enables the engine oil to be cooled directly from an ambient air from the cooling fans. SWEP and Alfa Laval brazed plate heat exchangers.

As a waterwater exchanger ie. We sell a very wide range of compact conventional heat exchangers at low pricesBrazed plate heat exchangers are extremely efficient for heat exchange. Heating water heating DHW heating drinking water heating separation exchanger biogas stations.

Plate type heat exchanger diagram. This manufacturing method is. Replacing and cleaning of the plates is a simple task because the plate stack can be opened easily.

Pressure drop delta PΔP is less than a plate heat exchanger. Because each of the plates has a very large surface area the plates provide each of the fluids with an extremely large heat transfer area. The flat plat collectors is basically a heat exchanger which transfer the radiant.

Milk chilling plants b. Each of the three methods for producing pipe has its advantages and disadvantages. Manuel Correia Guedes in Sustainability Energy and Architecture 2013.

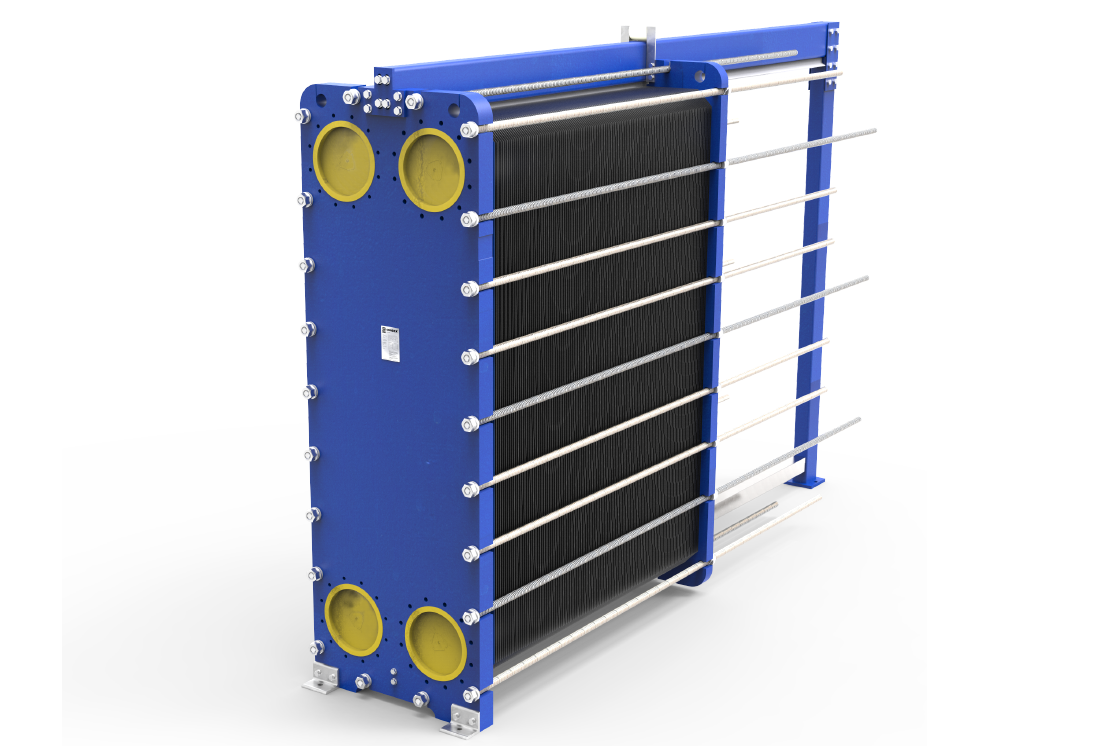

A plate type heat exchanger as illustrated in Figure 2 consists of plates instead of tubes to separate the hot and cold fluids. And unlike shell and tube heat. Plate heat exchangers weigh less require less space and are more efficient compared to other heat exchanger designs of the same size.

Suitable for higher pressures and temperatures compared to plate heat exchangers. Clarify the presentation of the message so that it is not too verbalistic In the form of words written or verbal only.

Advantages And Disadvantages Of Shell And Tube And Plate Type Heat Exchangers Cold Drawn Seamless Tube

How Plate Heat Exchanger Work Alfa Laval

All About Plate Heat Exchangers What You Need To Know

Plate And Shell Heat Exchangers Are Also Classified

0 Response to "Advantages and Disadvantages of Plate Heat Exchanger"

Post a Comment